Logan Cummings

Mechanical Engineer I @ Dispenza EngineeringM.S. Advanced Energy SystemsActively seeking new position in Climate

Introduction

I'm a Mechanical Engineer with experience in Mechanical Design and looking to break into the climate sector. At Dispenza Engineering, I've harnessed my design skills to craft innovative solutions for a wide range of businesses throughout all phases of the design cycle. I also perform in-house manufacturing and field work, diagnosing and resolving product design issues.A Harvey Scholar armed with a Master's in Advanced Energy Systems from the Colorado School of Mines, my education journey has been all about diving deep into the energy transition, covering everything from electrochemical devices to advanced thermodynamics and energy for transportation. My expertise isn't just technical; it's driven by a genuine passion for energy innovation and solving big environmental challenges.I'm on the hunt for opportunities where I can blend my mechanical engineering background with my enthusiasm for climate action.

Hard Skills

Fixture Design, DFM, FEA, Tolerance Analysis, Mechanical Design, Assembly Management, DFA, RFQ Packages, CAM, CFD, Prototyping, Additive Manufacturing, Mold Design, CNC Operation, Technical Documentation

Soft Skills

Technical Writing, Presentation, Leadership, Team Dynamics, Concept Selection, Secondary Research,

Adaptability, Communication, Time Management, Problem Solving, Detail Oriented, Critical Thinking

Software

SolidWorks, SolidCAM, Fusion 360, Python, nTopology, MATLAB, EES, Abaqus, MathCAD, LabVIEW, Arduino

Designs

AirWeights

Design and Innovation: Led the design of 3D models and CAM for AirWeights, launching a successful CNC component business. Demonstrated expertise in CAD and CAM software, crucial for engineering projects requiring precision and innovation.

Prototype Development: Streamlined product development through five iterations, focusing on rigorous testing and redesigns. This mirrors industry standards for high-performance and reliability in coplex systems.

Manufacturing and Efficiency: Optimized CNC operations to enhance production efficiency, reflecting skills in manufacturing process management. Achieved over $100,000 in sales since October 2023, indicating strong market demand and project management prowess.

D300 Pan Tilt Unit

Field Rework and Product Improvement: Successfully performed technical adjustments on merchandise valued over $1,000,000, addressing and resolving factory vulnerabilities, demonstrating the ability to identify and rectify critical issues in high-value equipment.

Design Optimization: Proactively revised designs to eliminate additional flaws found during field rework, showcasing adaptability and a keen eye for enhancing product reliability and performance through iterative design improvements.

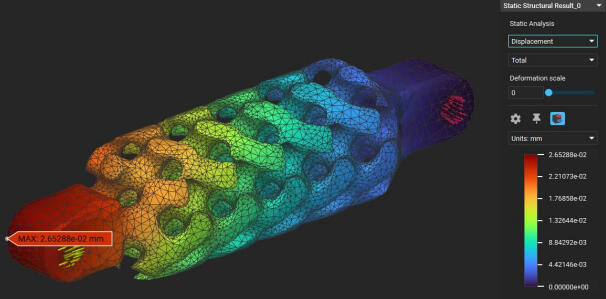

Engineering and Analysis for Tool Development: Led the mechanical design, hardware selection, and conducted Finite Element Analysis (FEA) for the creation and refinement of manufacturing tools for sensitive electronics, highlighting expertise in engineering principles and analysis to improve production capabilities.

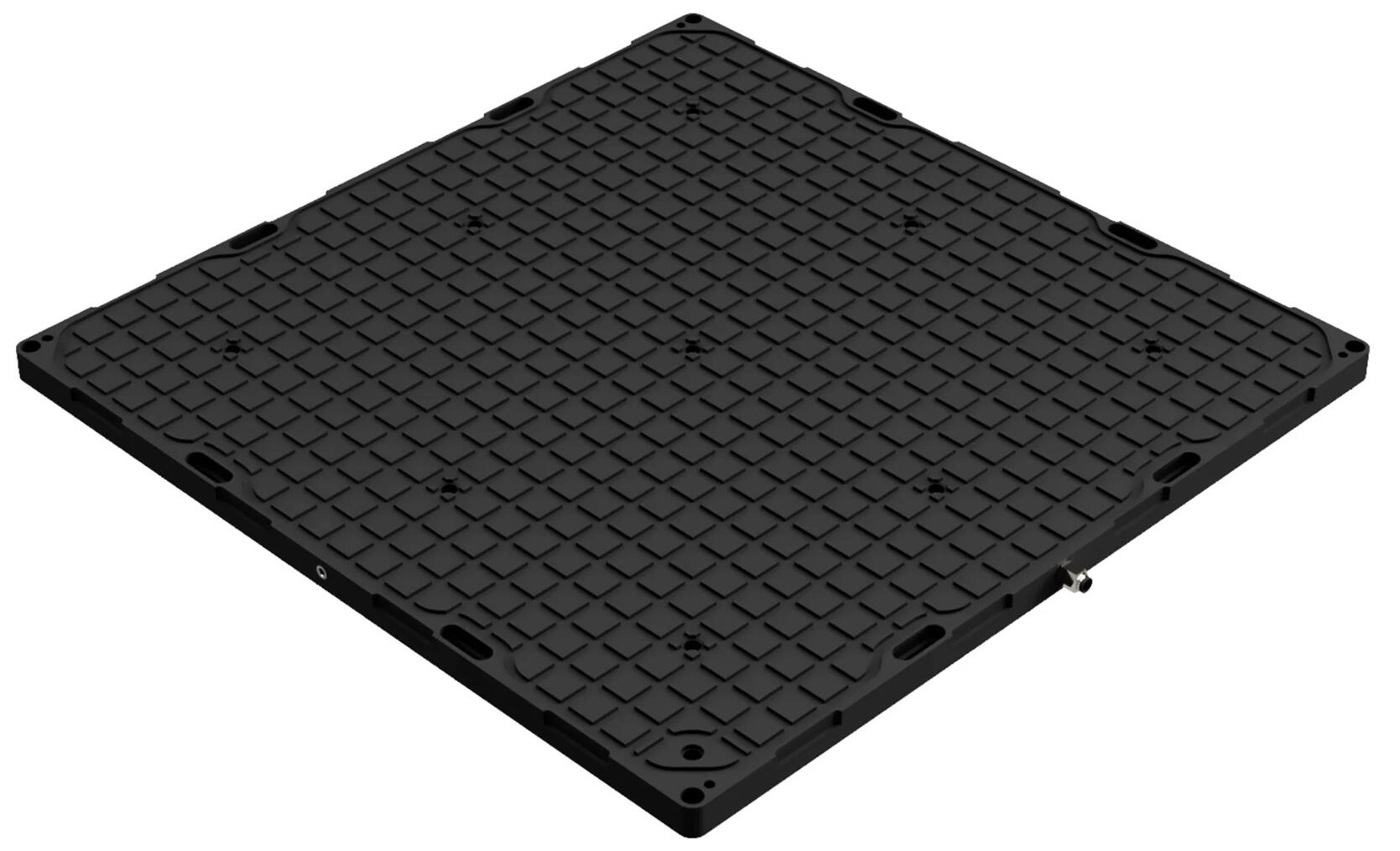

Compliant Mountain Bike Component

Lattice Design: Implemented additive manufacturing techniques to design a TPMS lattice structure for a mountain bike shock, demonstrating advanced CAD skills in SolidWorks and the ability to innovate in mechanical design for improved performance and compliance.

Advanced Analysis: Performed static analysis using nTop platform on the final TPMS lattice design under realistic load conditions, showcasing proficiency in simulation tools and understanding of material properties (AlSi10Mg).

Pioneered Workflow: Developed a comprehensive workflow from initial concept through design refinement and simulation, highlighting the capability to manage complex projects and integrate feedback into the design process and allowing for straightforward implementation of additional projects.

Residential PV Tracker

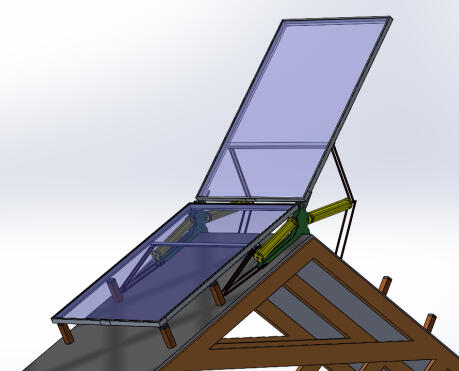

Residential Single Axis PV Tracker Module

Solar Tracking System Design: Engineered an innovative, cost-efficient residential photovoltaic (PV) solar tracking system, maximizing energy generation by dynamically adjusting panel angles in sync with the sun's path, employing pneumatics for actuation. Demonstrated advanced mechanical system design capabilities.

Structural Analysis: Applied Finite Element Analysis (FEA) to validate the structural integrity of the PV tracking system against diverse environmental conditions, including wind and snow loads. Showcased proficiency in FEA methodologies, essential for ensuring durability and reliability in aerospace and other critical applications.

Design to Deployment: Excelled in advancing projects from initial concept to prototyping, rigorous testing, and refinement, culminating in successful deployment. This process underlines a comprehensive approach to design management, from requirements gathering to final implementation.

Surf Foil Family

Generative Design Implementation: Pioneered a generative design workflow for an extensive product family, enhancing True Ames' product diversity across various surfing environments, streamlining the design process for efficiency and innovation.

Product Development Efficiency: Halved the throughput time for launching new products, significantly speeding up the time-to-market and enabling rapid adaptation to customer needs and market trends.

Remote Operations Support: Provided continuous remote support for shop operations, ensuring seamless production and maintenance of quality standards for True Ames' surfboard fins, demonstrating adaptability and commitment to operational excellence.

Other Work

Precision Engineering Documentation: Advanced datum structures and Geometric Dimensioning and Tolerancing (GD&T) were utilized to meticulously compile Bills of Materials (BOMs) and Request for Quotation (RFQ) packages, enhancing the precision and clarity of project documentation.

Adaptive Project Management: Demonstrated exceptional adaptability and time management skills by efficiently handling multiple projects across diverse clients, crucial for fast-paced and multifaceted engineering projects.

Collaborative Technical Leadership: Took the helm in technical decision-making, leveraging strong collaboration with clients and colleagues to drive project success. This leadership role was pivotal in navigating complex engineering challenges inherent to design and manufacturing.

Rigorous Design Validation: Conducted comprehensive physical assembly and testing configurations to systematically validate design solutions, ensuring the reliability and performance of mechanical systems in demanding conditions.

Education

M.S. Advanced Energy Systems

"Through a unique interdisciplinary graduate engineering program, Colorado School of Mines (Mines) and National Renewable Energy Laboratory (NREL) are cultivating the rich opportunity landscape needed to develop these future innovators. The Mines/NREL Advanced Energy Systems (AES) graduate engineering degree program prepares energy professionals at the master’s level to address the full complexity of tomorrow’s infrastructure, economic, and environmental challenges."Areas of Study Included:

Advanced Engineering Thermodynamics

Fuel Cell Science and Technology

Design for Additive Manufacturing

Energy for Transportation

GPA: 3.88

B.S. Mechanical Engineering

Minor in Public Affairs - McBride Honors Program

Harvey ScholarshipGPA: 3.82 - Magna Cum Laude

Awards and Honors

Harvey Scholar

"Established in 2009, the Harvey Scholars program attracts standout students with a passion for service. The scholarship’s motto, ‘Pay It Forward’, reflects community values of generosity, gratitude, and concern for others. Programming includes luncheons with donors Hugh and Michelle Harvey, community-wide service activities, off-campus retreats and small group dinners.The Harvey Scholarship covers full tuition and mandatory fees for ten semesters at Colorado School of Mines. It also includes generous travel and enrichment grants to support scholars’ study abroad programs, research pursuits, and professional development."

Thomas Philipose Outstanding Senior Award - McBride Honors Program

"Named after Dr. Thomas Philipose, the first Principal Tutor of the McBride Program, this award is presented to the graduating senior who best represents the values and aspirations of the Program. Recognizing outstanding academic achievement, personal growth, and leadership, the award comes with a commemorative plaque and a check for $1,000."

FIRST Fellowship

"The First-Year Innovation and Research Scholar Training (FIRST) Fellowship offers an opportunity for select, highly motivated first-year students to participate in original research experiences coupled with a focus on innovation. FIRST fellowship recipients are awarded up to $1000 paid hourly to compensate for their time spent on research."

© Logan Cummings. All rights reserved.